For more than sixty years we have been doing business in the steel hot forging sector. A longevity that has its roots in the daily commitment, in the passion for our work and in the con-stant investment in technologies and machineries.

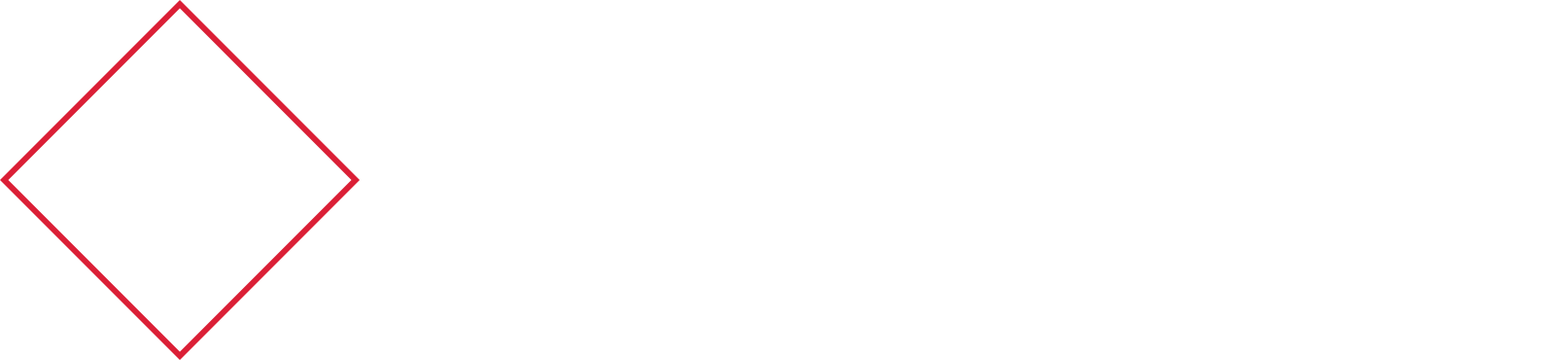

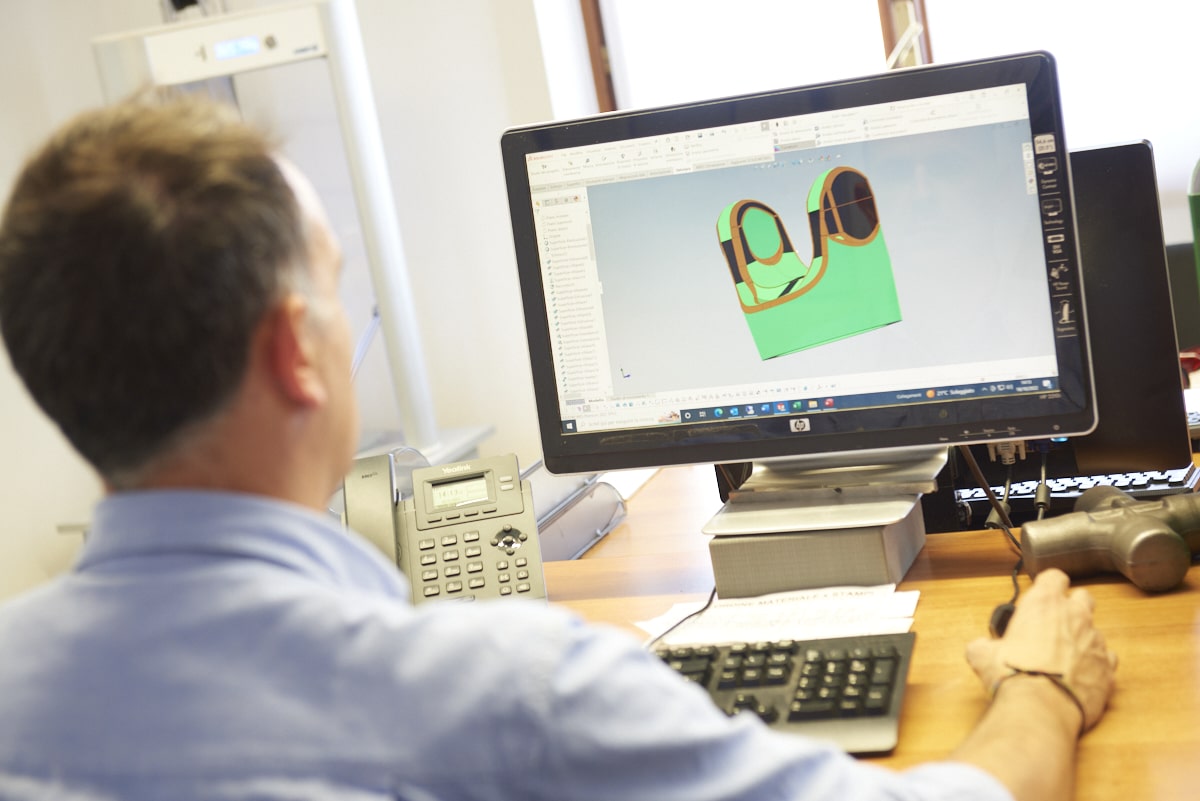

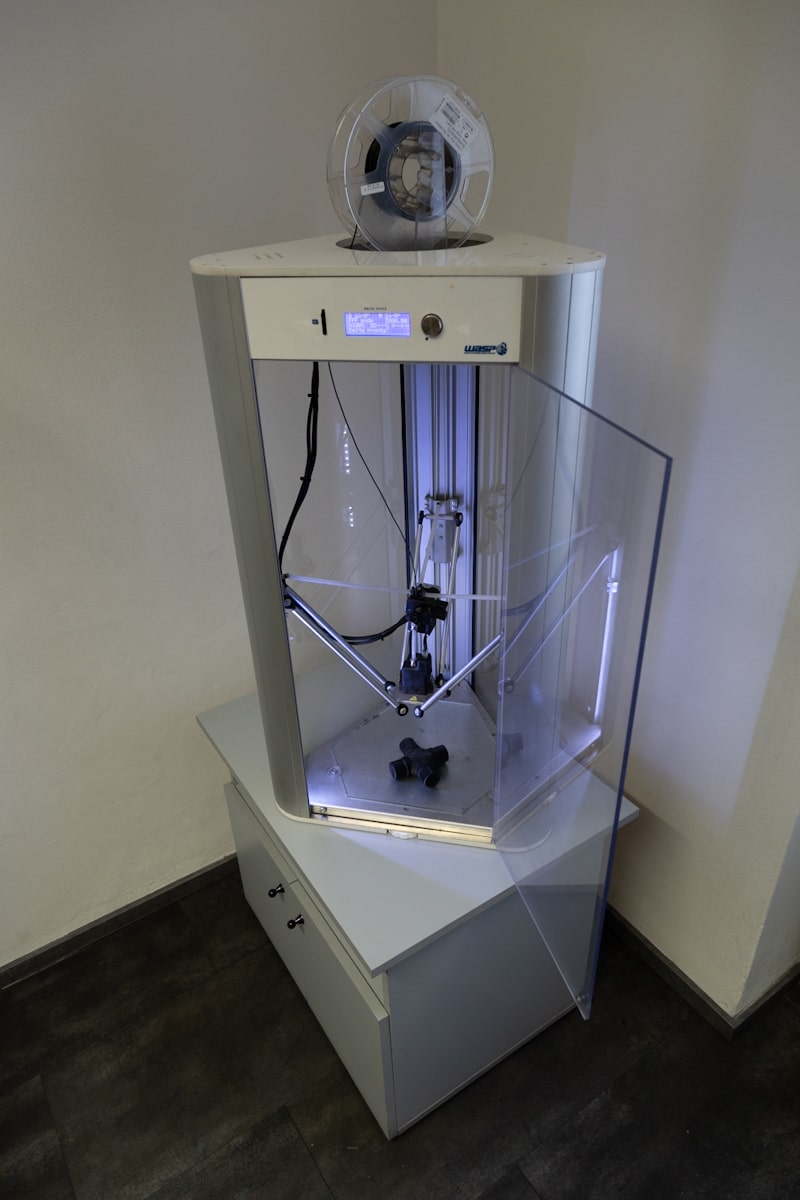

We believe that investing in technologies means investing in the quality of our products, in the safety and health of our staff, in the growth of our business. Over the years, we have namely combined the experience and ability gained in the field with cut-ting-edge technologies for the purpose of improving the business effectiveness, by increasing the productivity and the safety in the workplace.

All departments are interconnected each other thanks to constant investments using the “Industry 4.0” requirements, which have led us to an improvement in the business performance throughout the analysis of the data collected.

Production is completely realized internally, in the plant of Erba. Considering the steady increase in the demand of forgings, it has become necessary to expand the production capacity. Therefore, we have purchased a new area next to the historical plant, moving from a total surface of about 10.000mq to over 20.000mq.

INVESTING IN TRAINING AS A VALUE TO CREATE QUALITY

Every day we commit ourselves to pass down to our co-workers the expertise and the ability, but especially to trigger the set of values and traditions which distinguish the company itself and Bonanomi philosophy since its foundation. Human resources are at the heart of our project. For this reason, we care about safety at work: daily we carry out all the fundamental operational controls and increase the awareness on the matter among all our coworkers, to create a safe environment where working with as little risks as possible. Consequently, we are implementing an occupational health and safety management systems, according to the ISO 45001 standard.

OUR COMMITMENT TO A MORE SUSTAINABLE PRODUCTION

We try to reduce the environmental impact of our production processes, limiting emissions and avoiding waste of energy and raw materials that we consume, maximizing the recovery of waste to protect the area around us. Especially, over the years we have developed a system of energy con-sumption detection, which allows us to monitor all the production lines, with the aim of analyzing consumption and/or losses of the heating systems to get at the root cause and replace the less effi-cient ones. The aim is to obtain the UNI EN ISO 14001:2015 certification (Environmental Man-agement System) as soon as possible.